Dust Collection Wiring, New & Expanded Electrical Service

Background & Challenges

A leading manufacturer in the cabinet industry required a significant expansion of its manufacturing space to meet growing demand. This expansion necessitated a robust electrical infrastructure to support new machinery, a larger dust collection system, advanced lighting, and forklift charging stations. Moreover, the company wanted to improve operational efficiencies and expand throughout their upgraded facility.

The existing electrical framework was not designed to accommodate the increased load of new equipment and more complex workflows. Any upgrades needed to be strategic, ensuring both compliance with safety standards and room for potential future expansion.

Project Goals

Support Expanded Manufacturing

Improve Production Efficiency

Enhance Work Environment

Ensure Safety & Compliance

Work Performed

Dust Collection System Wiring

Dust Collection System Wiring

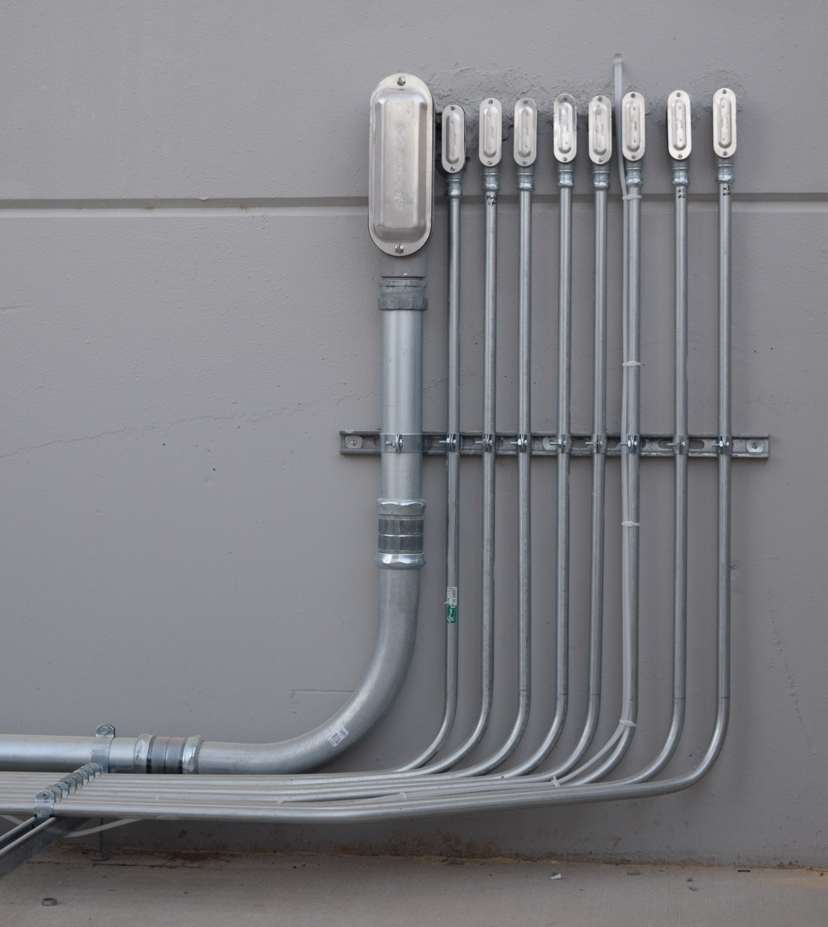

New & Expanded Electrical Service

Installed 400-amp circuits

Motors & Safety Switches

Seamlessly integrated into the manufacturing lines for saws, sanders, shapers, and other small equipment.

Wiring & Circuit Boxes for Manufacturing Lines

Forklift Charging Stations

Lighting & Ventilation

Co-ordinated Wiring for New Equipment

Compliance